1

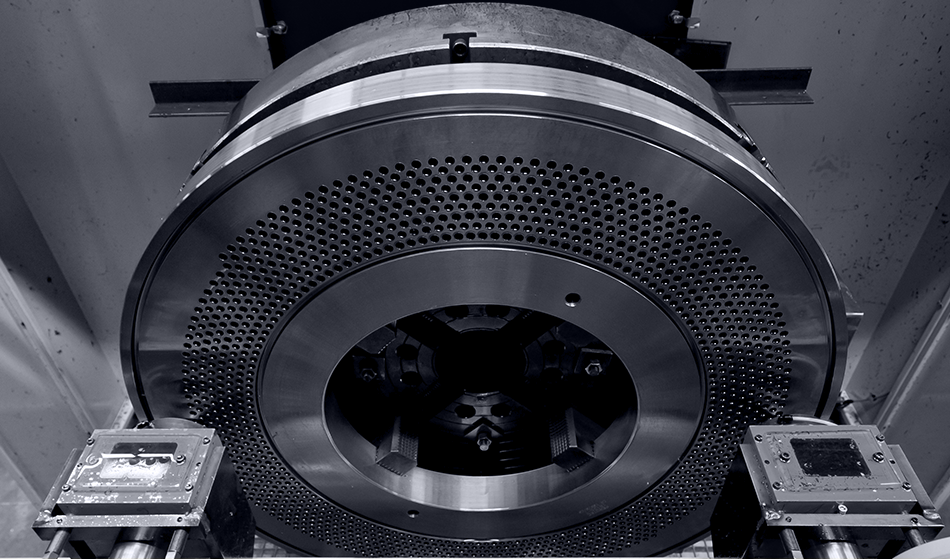

Material Selection and Preparation

We meticulously choose high-quality raw materials and subject them to secondary steelmaking processes, including degassing billets for purity and consistency. Depending on requirements, we offer materials such as X46Cr13/4Cr13 stainless steel or 42Crmo/20CrMnTi alloy steel, with the option for custom materials.

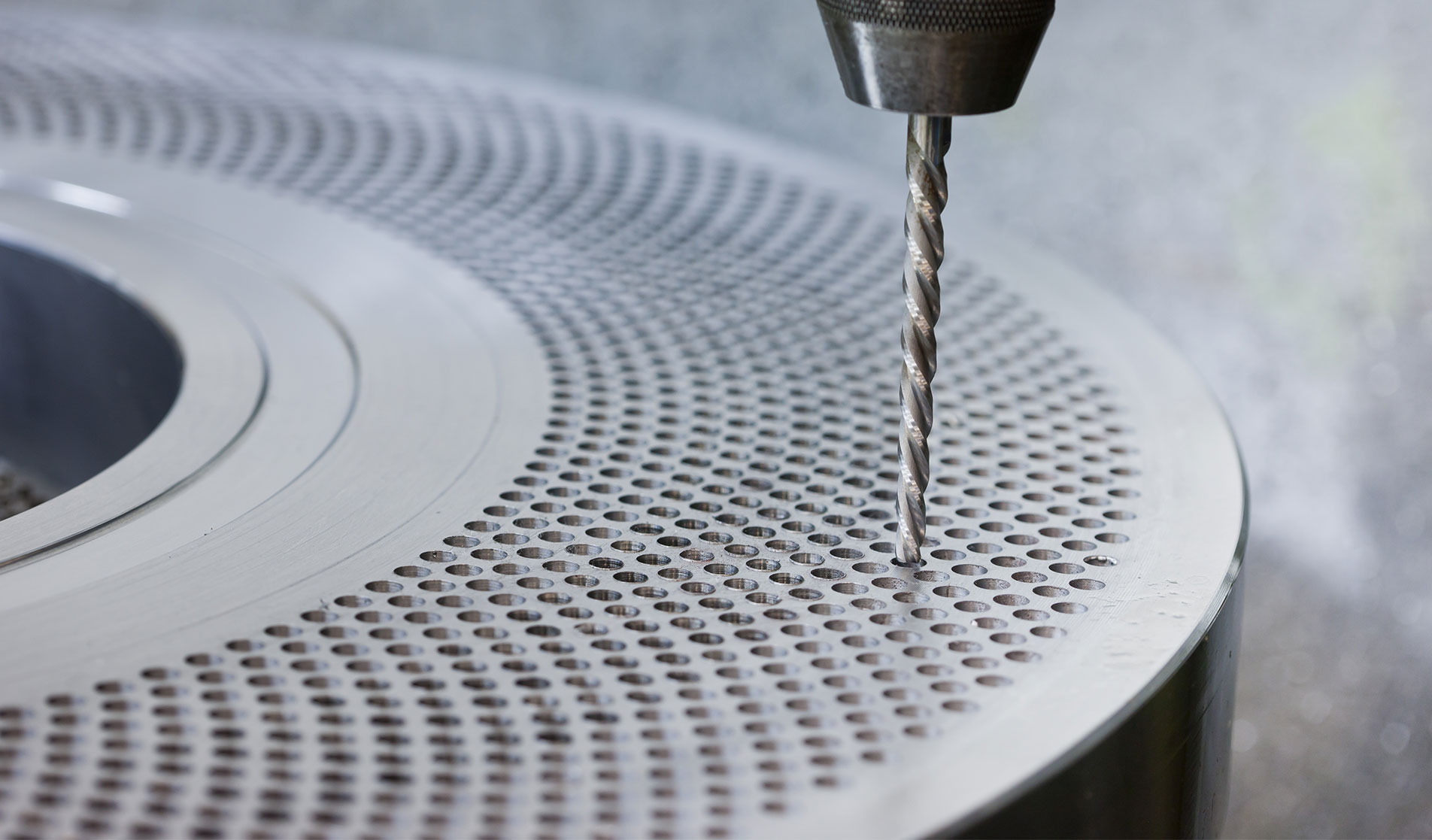

2

Precision Drilling and Forming

Using advanced equipment like imported gun drills and multi-station drills, we ensure precise hole formation in a single operation. This results in high-quality finish and optimal performance for feed production, enhancing both efficiency and aesthetics.

3

Thorough Heat Treatment

Employing a combination of vacuum furnace and continuous quenching furnace, we guarantee comprehensive heat treatment to enhance the durability and longevity of our ring dies.

4

Customization and Quality Assurance

We collaborate closely with customers to design compression ratios and strengths as per their requirements. Every ring die undergoes meticulous microscopic examination to ensure top-notch quality and consistency, providing peace of mind to our clients.

This detailed process ensures that each ring die we produce meets the highest standards of quality and performance, tailored to our customers' specific needs.