JARAY: Ultimate Ring Die Partner for Wood, Biomass and Feed Pellet Mill Machines | JARAY Ring Dies from China

Performance Guaranteed Ring Dies from China for your Feed, Biomass & Wood Pellet Mills

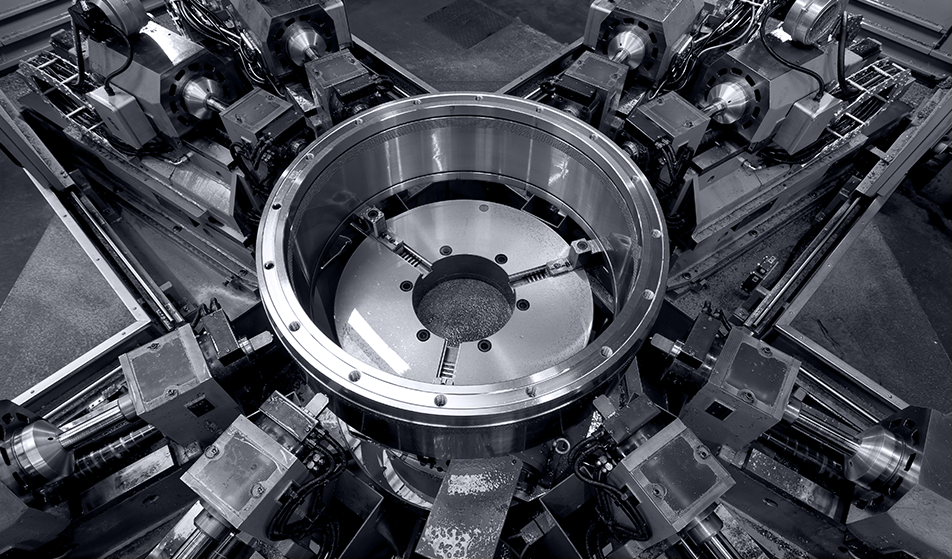

Crafted with precision engineering to thrive in the rigorous conditions of feed, biomass, and wood pellet mills , our JARAY Ring Die from China epitomizes the pinnacle of meticulous craftsmanship. Engineered to adapt to the dynamic requirements of the ever-evolving market , our China Ring Die embodies cutting-edge innovation, ensuring unparalleled performance, unwavering quality, and unmatched reliability seamlessly enhancing your pellet production operations .

Each Ring Die from China is meticulously constructed using premium-grade materials and state-of-the-art automation technologies from JARAY China Ring Die, resulting in a solution precisely customized to meet your production needs. Committed to upholding industry benchmarks, our JARAY China Ring Die ensures that every pellet manufactured adheres to the stringent quality criteria demanded universally by pellet consumers across the globe.

Elevate your pellet production process to unprecedented levels of efficiency and performance with our Ring Die from China, meticulously designed and assembled to optimize your workflow and propel your operations towards excellence. Experience the reliability and superior durability of JARAY Ring Die from China, the trusted choice for feed, biomass, and wood pellet manufacturers worldwide.

CPM FEED, BIOMASS & WOOD RING DIE FROM CHINA

BUHLER FEED, BIOMASS & WOOD RING DIE FROM CHINA

SZLH FEED, BIOMASS & WOOD RING DIE FROM CHINA

ANDRITZ FEED, BIOMASS & WOOD RING DIE FROM CHINA

MUZL FEED, BIOMASS & WOOD RING DIE FROM CHINA

VAN AARSEN FEED, BIOMASS & WOOD RING DIE FROM CHINA

PTN FEED, BIOMASS & WOOD RING DIE FROM CHINA

CPP FEED, BIOMASS & WOOD RING DIE FROM CHINA

TPM FEED, BIOMASS & WOOD RING DIE FROM CHINA

IDAH FEED, BIOMASS & WOOD RING DIE FROM CHINA

FLAT RING DIE FOR PELLET MILL FROM CHINA

Get in touch with us now to explore our cutting-edge JARAY China Feed, Biomass, and Wood Ring Dies.

Request a personalized quote tailored to your specific budget and requirements, and discover the ideal solution for your pelletizing needs.

How Are Ring Dies Made in China? A Comprehensive Guide to Ring Die Manufacturing Process

Explore the advanced manufacturing excellence behind the JARAY Ring Die from China, precision-engineered to maximize efficiency and durability in wood, biomass, and feed pellet mills. Each China Ring Die is crafted through a meticulous process from initial forging to precision machining and final packaging, ensuring consistent quality and superior performance. JARAY Ring Die in China is designed for seamless compatibility with leading pellet mill brands, including CPM, Bühler, SZLH, Andritz, MUZL, Van Aarsen, PTN, CPP, TPM, IDAH, Prodesa, La Meccanica, Kahl, Salmatec, and Munch, delivering reliable operation and longer service life for global pellet producers.

Forging the Ring Material

High-quality metal is rolled into a perfect ring, forming a durable base for the Ring Die.

CNC Machining for Precision Shaping

The ring is precisely shaped to exact diameters and specifications for optimal performance.

CNC Gun Drilling

Holes are drilled with high precision to ensure uniform pellet size and consistent production.

Counter Drilling

Holes are refined to be smooth and free of imperfections, enhancing material flow.

Table Drilling

Additional holes are drilled at precise angles, optimizing the die’s efficiency.

Heat Treatment

The die is strengthened through controlled heating and cooling, increasing wear resistance.

Hole Filling/Sealing

Drilled holes are sealed to protect against corrosion and maintain die integrity.

Anti-Corrosion Coating

The die is strengthened through controlled heating and cooling, increasing wear resistance.

Final Packaging

The Ring Die is securely packed in a wooden case to ensure safe transportation and storage.

High-Quality Dies for Maximum Efficiency

Optimized performance with JARAY Ring Dies from China for Pellet Mills

JARAY China Ring Dies are designed to deliver exceptional productivity and high compression ratios, making them the preferred choice for high-density products. These Ring Dies from China are ideal for producing a wide variety of products, including compound feeds, alfalfa, sugar beet, fertilizers, minerals, wood, straw, biomass, and both household and industrial waste.

Superior Strength and Durability

Crafted from forged rings for unparalleled durability with JARAY Ring Dies from China

Manufactured from high-quality forged rings, JARAY Ring Die from China offers guaranteed strength and longevity. These China Ring Dies are engineered to withstand the rigors of continuous operation, ensuring reliable performance across various applications. The robust construction makes them adaptable to all types of products, providing consistent, high-quality output.

Technical Expertise and Customization

Tailored solutions for diverse pelleting needs with JARAY Ring Dies from China

At JARAY, we pride ourselves on technical expertise and the ability to provide customized solutions. Our production process includes comprehensive heat treatment to ensure the durability and effectiveness of each JARAY Ring Die from China. We cater to diverse requests, offering dies with cylindrical, conical, or clamp fittings to meet the specific needs of our customers.

Personalized Service and Support

Dedicated assistance to maximize your production efficiency with JARAY Ring Dies from China

Our sales advisors are committed to providing exceptional service and support to our client. They work closely with users of JARAY China Ring Dies to ensure optimal performance and productivity. By understanding each customer’s unique requirements, we offer personalized recommendations on bore type, alloy selection, open surface area percentage, and counterboring type.

Precision Engineering for Improved Performance

Enhance your pellet mill's output with precision-engineered JARAY Ring Dies from China

Several critical factors contribute to the superior performance of JARAY Ring Die from China, including precise drilling diameters, optimized compression ratios, strategic hole patterns, and specific types of counterbores. Each element is meticulously engineered to enhance efficiency and output in your pellet mill.

High-Grade Steel from China for Exceptional Hardness

Achieve long-lasting results with durable, high-hardness JARAY Ring Dies from China

JARAY Ring Dies in China are crafted from high-grade steel, ensuring exceptional hardness and durability. The Rockwell C-scale hardness is tailored to withstand demanding pellet production conditions, allowing the dies to maintain integrity under high-pressure operations over time.

For Versatile Applications for Diverse Industries

Adaptable solutions for various pelleting applications with JARAY Ring Dies from China

JARAY China Ring Dies are suitable for a wide range of industries. Whether producing animal feed, biomass pellets, or industrial products, these Ring Dies from China provide reliable and efficient solutions. Their adaptability to different products and production requirements makes them invaluable for any pellet mill operation.

Empowering Global Pellet Production

Extensive Compatibility for Various Pellet Mills with JARAY Ring Dies from China

Our JARAY Ring Dies in China integrate seamlessly with a wide range of pellet mills, including CPM, Andritz, Bühler, Amandus Kahl, MuNCH-Edelsthl GmbH, Prodesa, Salmatec, La Meccanica, and Buskirk. Leveraging advanced manufacturing capabilities, these dies meet exact specifications and compatibility requirements of leading pellet mill brands. Whether you operate a CPM, Andritz, or other pellet mill, JARAY China Ring Dies deliver consistent performance, exceptional durability, and precise pellet production, empowering pellet manufacturers worldwide to achieve maximum efficiency and productivity in {Location} for {Location} to {Location} in {Location} for {Location} for {Location} for {Location} for {Location} made for {Location} designed for raw materials available at {Location} suitable for all types of raw materials at {Location} of {Location} for {Location} suitable to various raw materials at {Location} exclusively made for {Location} at {Location}|||

Frequently Asked Questions

We strive to provide as much information to you as possible. But if there is something more that you would like to talk about, You can always contact us on +86 186 5120 4359

What types of ring dies do you manufacture?

We specialize in manufacturing Ring Dies for Feed Pellet Mills, Biomass Pellet Mills, and Wood Pellet Mills. Our Rings Dies are designed for high-volume processing of various animal feed materials like fish feed, cat litter feed, shrimp feed, cattle feed, pure forage (grass) feed pellets, complete diet feed pellets, concentrated feed pellets and premix feed pellets, biomass materials, making them ideal for pelletizing industries. With our Ring Dies, you can trust in the quality and reliability of our equipment for your pelletizing needs.

What is the capacity of your Ring Dies manufacturing unit?

Our facility boasts state-of-the-art automated CNC machines, gun drills, and a heat treatment facility. This advanced infrastructure enables us to produce Ring Dies efficiently, ensuring both quality and performance. With our capabilities, we can manufacture up to 3000 dies annually.

What size of pellets can be produced with your Ring Dies?

Ring Dies for feed pellet mills are available with pellet sizes ranging from 0.8mm to 16mm, offering versatility for various feed types and animal needs. These Ring Dies boast a durable working life of up to 000 hours, ensuring prolonged efficiency and performance.

Similarly, Ring Dies designed for biomass and wood pellet mills accommodate pellet sizes from 6mm to 30mm, catering to diverse biomass materials and applications. With a robust construction, they also deliver an extended working life of up to 000 hours, maximizing productivity.

Can you produce Ring Dies tailored to specific models of Pellet Mills, or are you able to manufacture them according to our provided drawings?

We have the capability to manufacture ring dies for a wide range of pellet mills, covering various brands including CPM Pellet Mills, Buhler Pellet Mills, Prodesa Pellet Mills, Andritz Pellet Mills, La Maccanica Pellet Mills, Salmatec Pellet Mills, Kahl Pellet Mills, Muench Pellet Mills, PTN Pellet Mills, CPP Pellet Mills, TPM Pellet Mills, IDAH Pellet Mills, SZLH Pellet Mills, MUZL Pellet Mills, Van Aarsen Pellet Mills. Whether you have a specific model from these manufacturers or require customization, we can accommodate your needs. Simply provide us with the model number of your pellet mill, and we'll tailor the ring dies accordingly. Additionally, if you have drawings outlining your specifications, we can manufacture according to those as well, ensuring precision and adherence to your exact requirements.